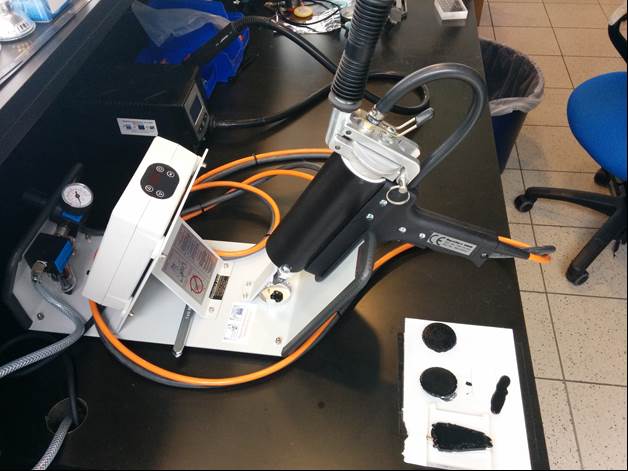

Low pressure molding system

Description

Low pressure molding system Optimel OM100 is a semiautomatic dispensing device with integrated melting tank for manual molding of electronic assembly.

Capacities

- Suitable for molding samples, prototypes and pre-series

- Maximum melting capacity is up to 1 kg/h

- Maximum processing temperature is 250°C

- Broad application spectrum due to different nozzle geometries

- Recommended for thermoplastic materials as polyamide and/or polyolefin hot melts

- No harmful fumes from the molding process.

Applications

Low pressure molding system Optimel OM100 is used for

- manual molding of electronic assembly like PCBs, sensors, switches, batteries, connectors and etc.

- protection assembly from environmental issues as moisture, elevated temperature, chemicals, dust, mechanical impact and etc.